Seminars on sailing are a great way to keep the juices flowing in the winter. The menu below is a summary of the seminars I have already prepared. I can also develop custom seminars for dedicated audiences. Interested? Need to learn more?

Drop me a note joe@joecoopersailing.com and let’s discuss what can be done to keep your group fired up in February.

PASSAGE MAKING

Preparing for your next “long passage”: This seminar discusses Seamanship and 8 things to think about before you undertake any voyage so we don’t read about you in WindCheck. Regardless of the size of boat and the intended passage, whether it is to Block Is. Nantucket, Maine or Bermuda and beyond. The thinking needed is the same regardless of the destination. This seminar discusses key elements of the boat to be reviewed before leaving the dock.

The teering cables on this 40 footer are mis-aligned. This will ultimately damage both the cables and the quadrant.

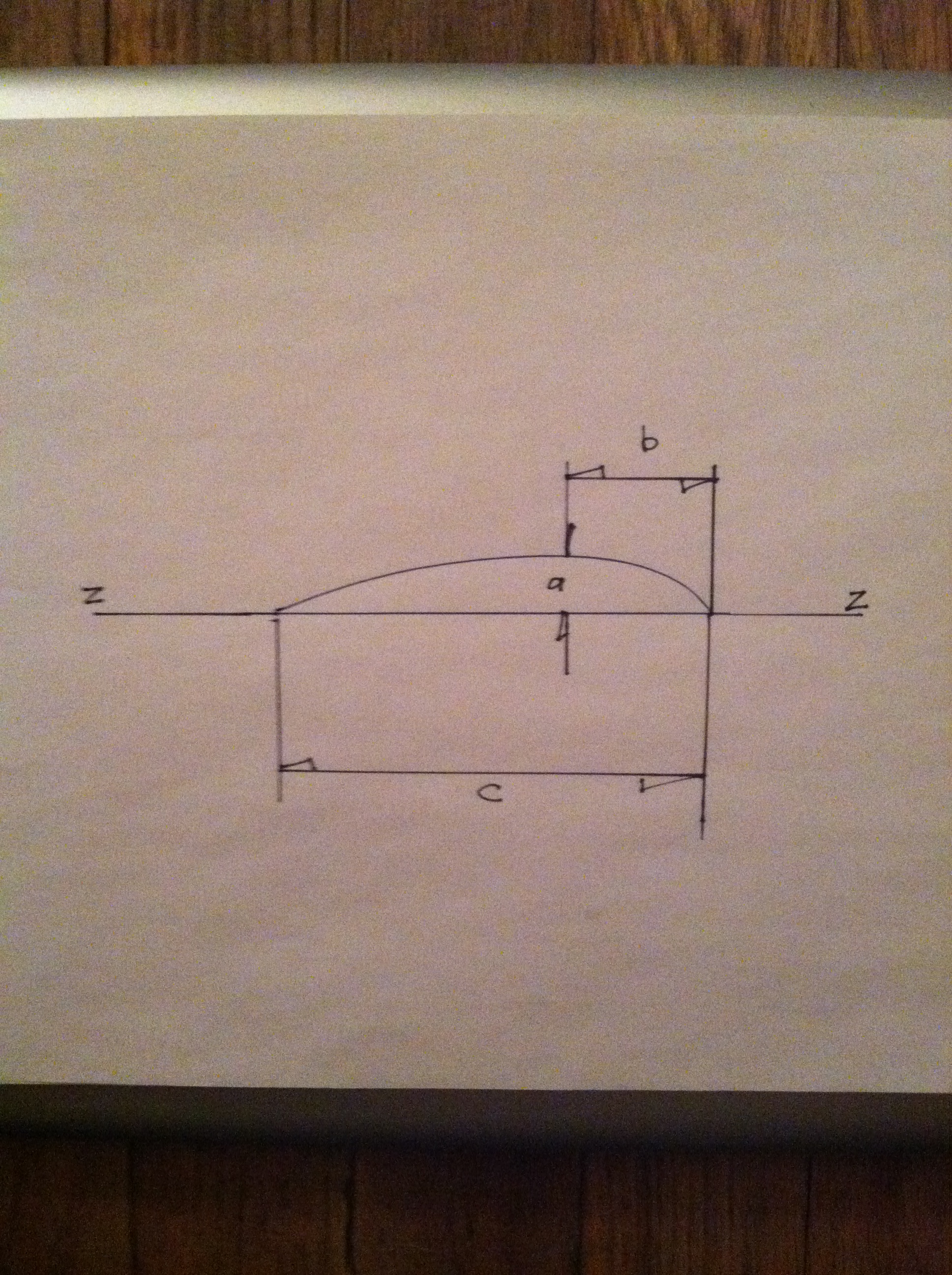

FULL LENGTH BATTENS

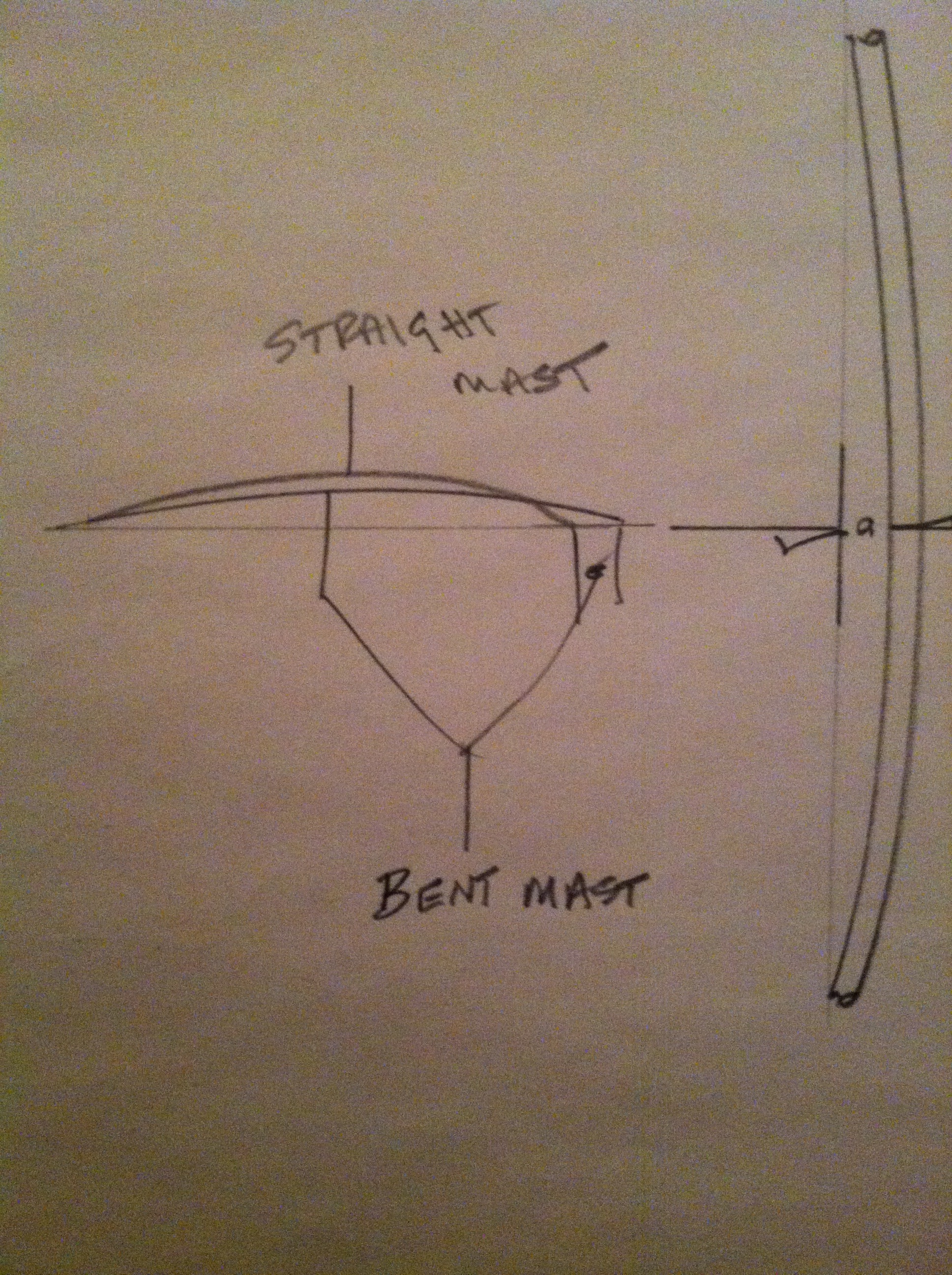

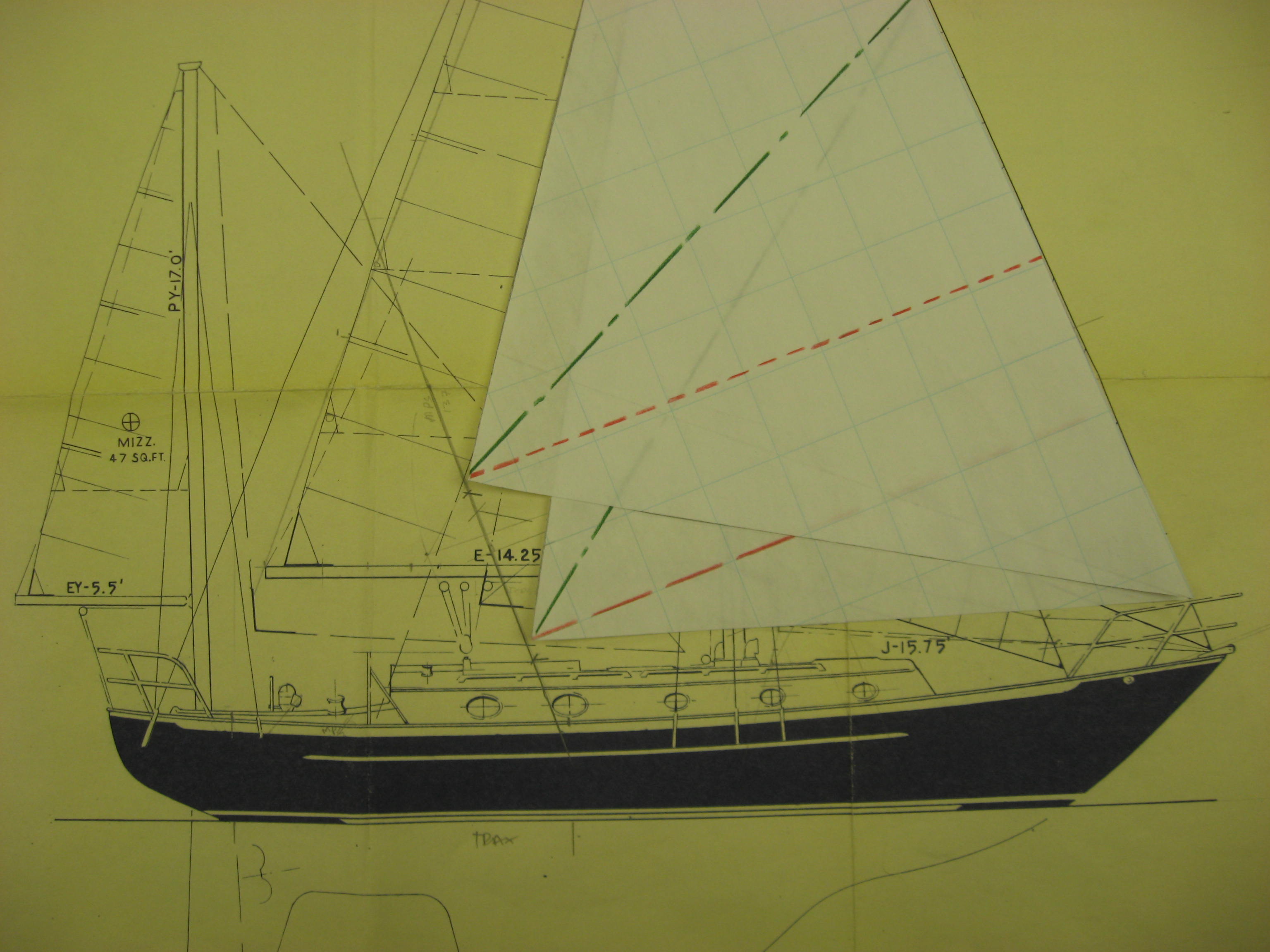

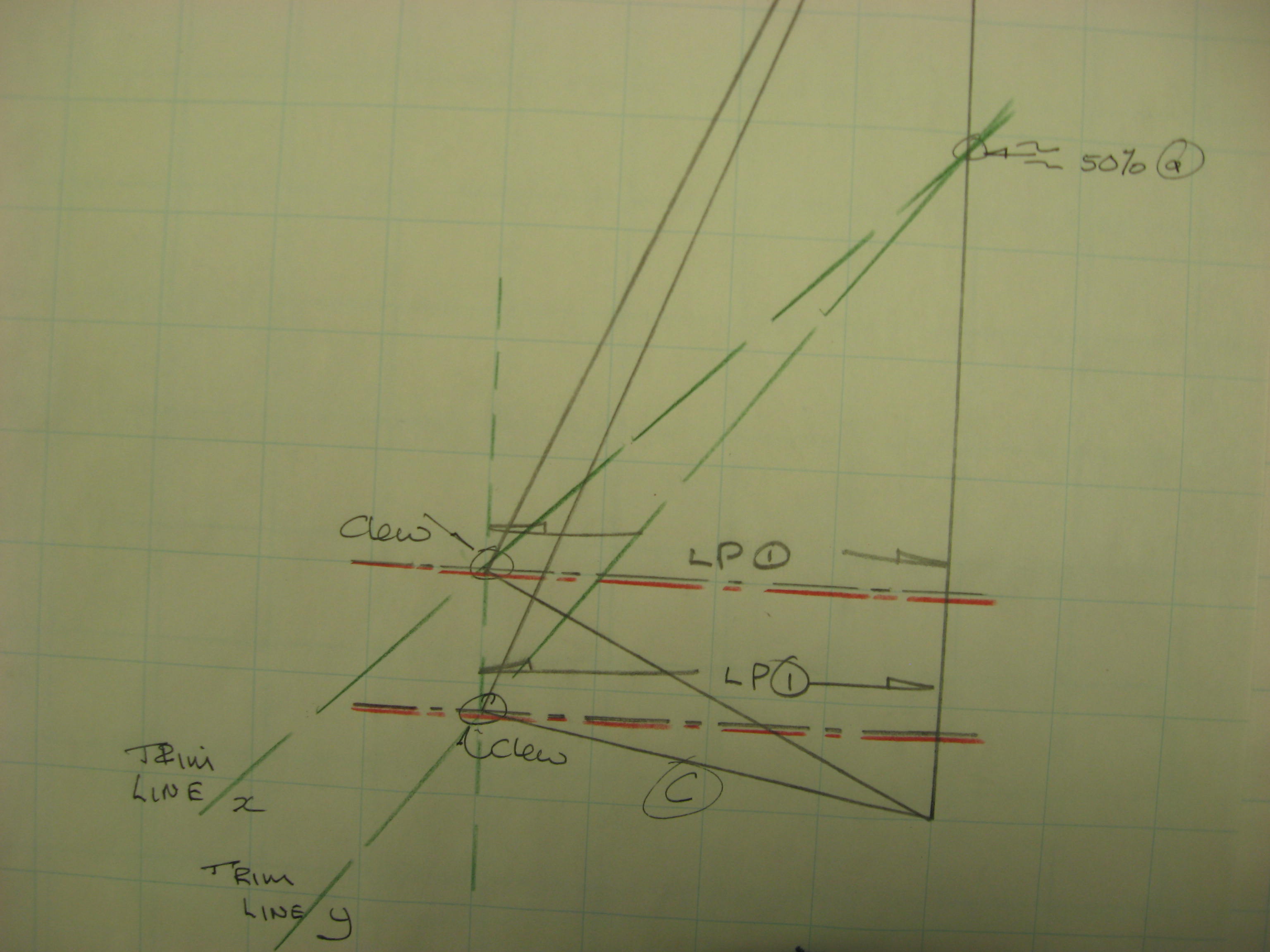

Separating the hype from reality: Just what is the VALUE in a FB SYSTEM? This seminar discusses the aerodynamics behind the FB phenomenon, the realities for most sailors with “normal” boats, the hardware, its use, cost and the relative value for sailors.

Full Length battens CAN provide los of roach, but in this case there is no backstay. BUT this is a custom built boat intended to have no backstay but rather runners.

In order for a FULLY BATTENED sail to REALLY slide up and down easily demands a comprehensive look at the sail, mast, the sailing plans plus how YOU like or want to sail.

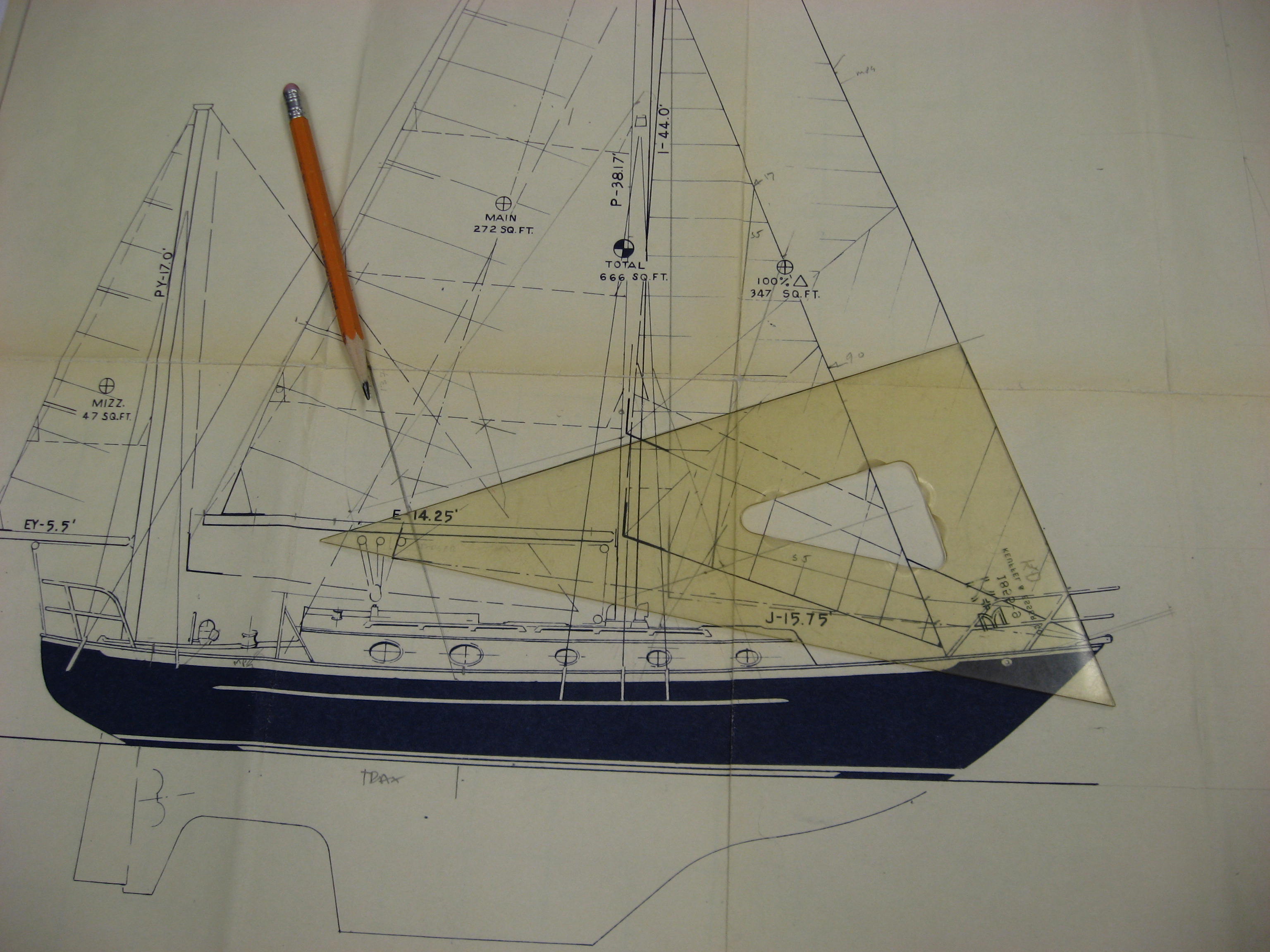

SAILCLOTH AND SAILS

Separating marketing from facts to get to Value: A discussion of sail cloth, details to look for and why for various types of sailing. What does “Premium Dacron” really mean? Why every sail maker has “The world’s best sails” What’s the difference? Why the price spread? Woven, Laminates, fibers, molded, not molded, a glossary and guide to sail-maker speak.

Or a woven material? In this case a full battened mainsail made from woven Vektron on a Beneteau 40.7. What gives YOU the best VALUE for your sailing?

CRUISING SAILS & RIGGING:

Options for sail inventory: How to set up your boat for your cruising goals, now and 5 years out. What you need, why and how to maximize Value without a boat full of sails.

A cruising kite is really an easy sail to get comfortable with and it is a great VALUE when sailing in medium air, the condition most passages are made in.

A “Solent” stay is a good way to have a small sail without having to “change” headsails when the roller headsail is too much sail. They are easy to install and can greatly expand the wind speed you feel comfortable sailing, pretty quickly.

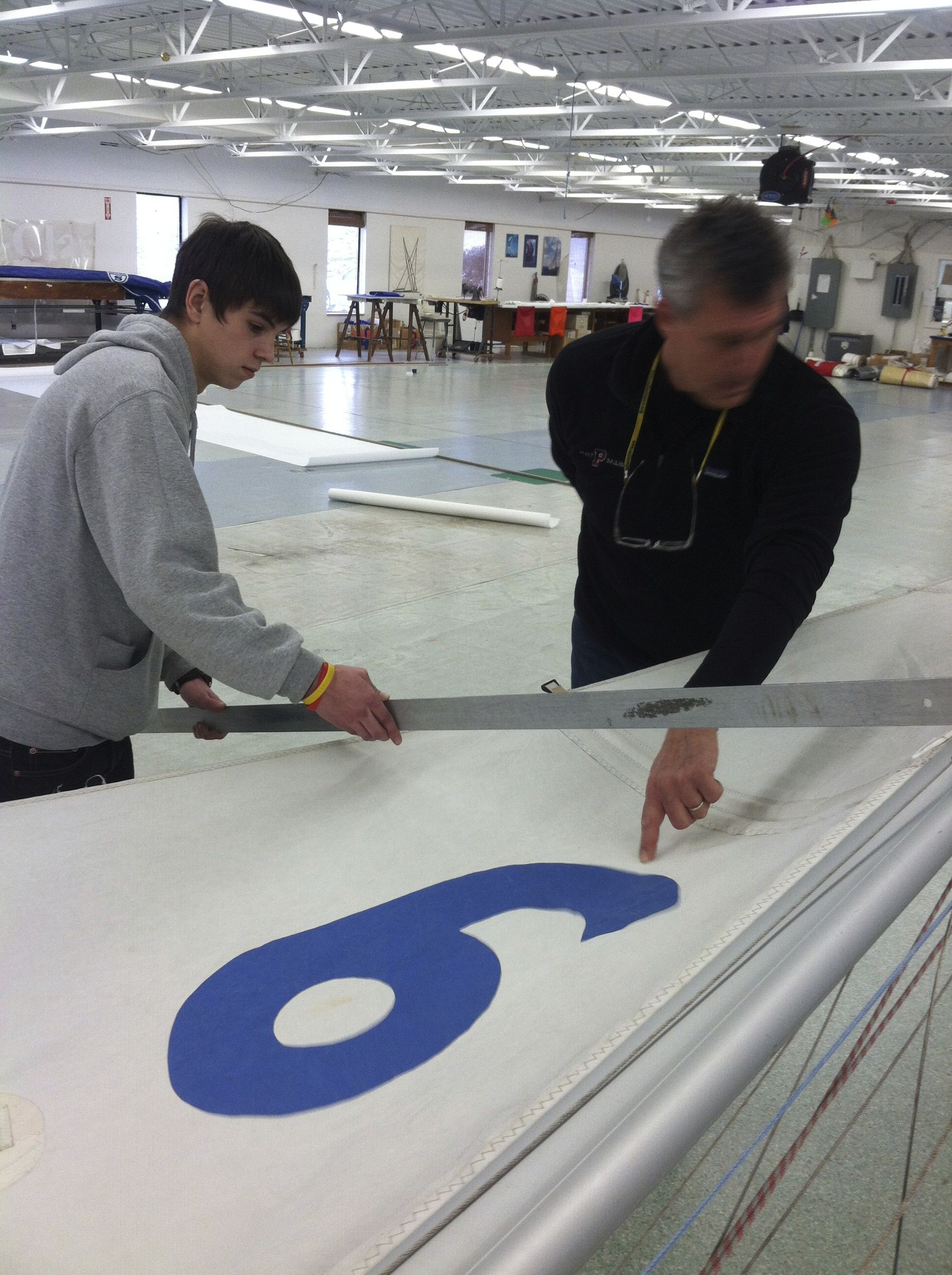

PREPARING FOR SUCCESSFUL RACING:

It’s not just wet sanding the bottom: A review of the steps the good guys take to give themselves the best shot at being successful.

Even for low key racing, the hard work is before you leave the dock. © Don Miller Photography. Bermuda 1-2 start. 2007

Even for single-handed events a team is an integeral component of the program. Spreading the passion for sailing to my son, as my dad for me.

THE AMERICA’S CUP:

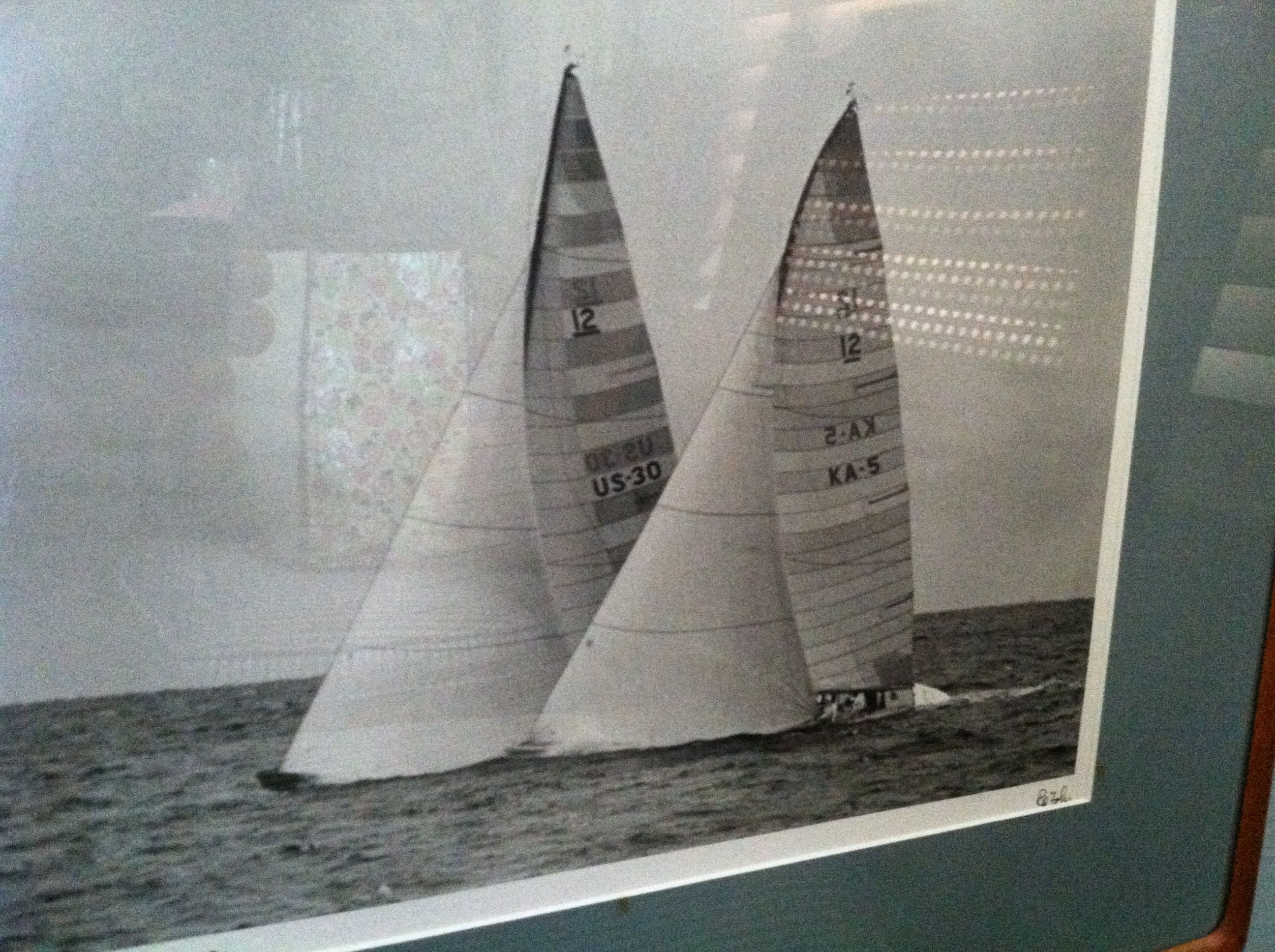

How a 7-year old kid ended up in two America’s cups. A look back thru the history of the Australian challenges for the America’s Cup beginning in 1958. How Australia got into the act, how a 7 year old kid was infected with the disease and what it was really like sailing a 12 meter in the late 70’s and early 80’s. Cooper was the youngest crew in 1977 and the boat keeper on Australia in 1980-working for the syndicate for 18 months and sailing as Grinder/Sewer man.

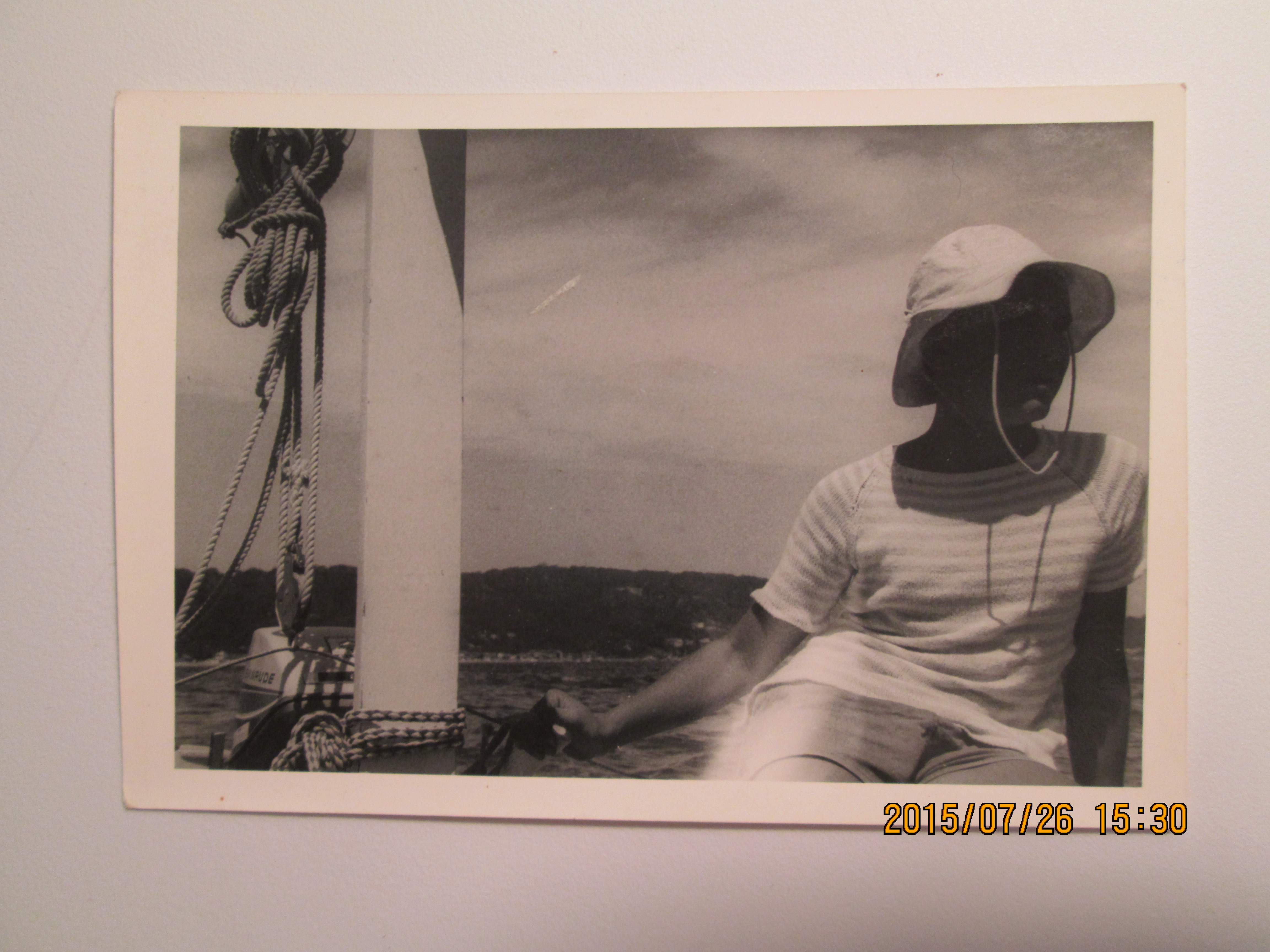

One of the signature images that lured me to the America’s Cup. The 12 meter Dame Pattie practicing on Sydney Harbor in 1967. I was 12 years old.

13 years later: Crew members from the Australian teams were popular and coveted guests at Newport’s summer parties. The Australie Challenge, July 1980. The beginning of the end…..

A PASSION FOR SAILING: (NEW- First presentation at Black Rock YC, second to be at Stamford Yacht Club 28 Jan 2016)

A life spent sailing & reflections on key areas of sailing that have shaped my life: Family, community, independence, experiences & personal philosophy.