A reader on LinkedIn posted a response-comment-observation regarding FLB and conventional battens with respect to in-mast furling so I will add this essay as a small side bar. My apologies I do not have many pictures for this subject, so you will have to read it, not look at it…

The question posed by this fellow is this:

And then there is the roller furling main! New experience for me as I have always sailed a traditional main (with battens). Very difficult to get used to looking at my main with the foot not fixed to the boom. My sail does have battens but the one nearest the head had to be removed to allow for the sail to be completely furled within the mast. I have been told that battens are not really needed in the furling main but started showing up because there was a “demand” for them. i like to convenience, especially when single handling, but………..would appreciate comments.

First a bit of background/History:

Most of us know that the original in-mast furling was invented and brought to market by Ted Hood, sometime in maybe the early 1970’s. They were unique at the time, had the Hood Cache and were almost the default spar on a long list of various sized Little Harbor yachts and then later other yachts particularly bigger ones, up to 80 footers which were big then.

Compared to the current crop of in mast furling spars, the Hood spars were really easy to work with from a sailmaker’s perspective. Not the least because they were designed by a sailmaker rather than a mast maker. There are two primary reasons related to this ease: The cavity into which the sail rolled was large. Second, the slot through which the sail passed was wide, perhaps an inch or more. Boat for boat both these items were larger than the same parts on spars today.

Between the time of the Hood Spars introduction and the early/mid 1980’s Hood was the 800 Lb Gorilla: There was Hood Sailmakers and Hood Yacht Systems with the latter incorporating the Sto-Away masts and later on an in-boom furling arrangement for a time plus the Hood Sea Furl furler, another virtual monopoly-No Harken, Profurl, Schaefer, Facnor, Furlex. There were a couple of older makes of furling (not reefing) head stays, one by Hyde and another by Stearns but they were not designed for using the headsail reefed. There was a particular part of the Hood Sea Furl Systems that made this viable. Regardless, if you wanted an in mast furling spar you went to Ted.

But things change. Hood sailmakers was sold in 1986, which is when I went to work for the new owner but Ted kept Hood Yacht Systems and brought it with him from Marblehead/Little harbor to Melville in Portsmouth RI.

Over time other mast makers began copying the Hood Spar, but of course they needed to be among other things, cheaper than the original (Hood Spar) in order to get a foot in the door. Anyway we now fast forward to the 21’st. C. Hood Yacht Spars was sold to the UK distributor of Hood Spars who sold it to another UK spar company who eventually went broke. Hood Yacht SYSTEMS, largely the furler’s, remains in business based in Florida and is a division of POMPANETTE. Roughly parallel with this progression many spar makers who used to do production aluminum spars have switched over to carbon and so today there are three remaining heavy weights in the production aluminum spar (In–mast furling) business:

Z spars, Charleston Spars/SparCraft both French and Selden, Swedish.

And on the edges of the In-mast terrain there are, or used to be, a couple of products you can bolt on to the back of the existing spar and some folks have taken a normal headsail furler and attached that to their spar with custom parts.

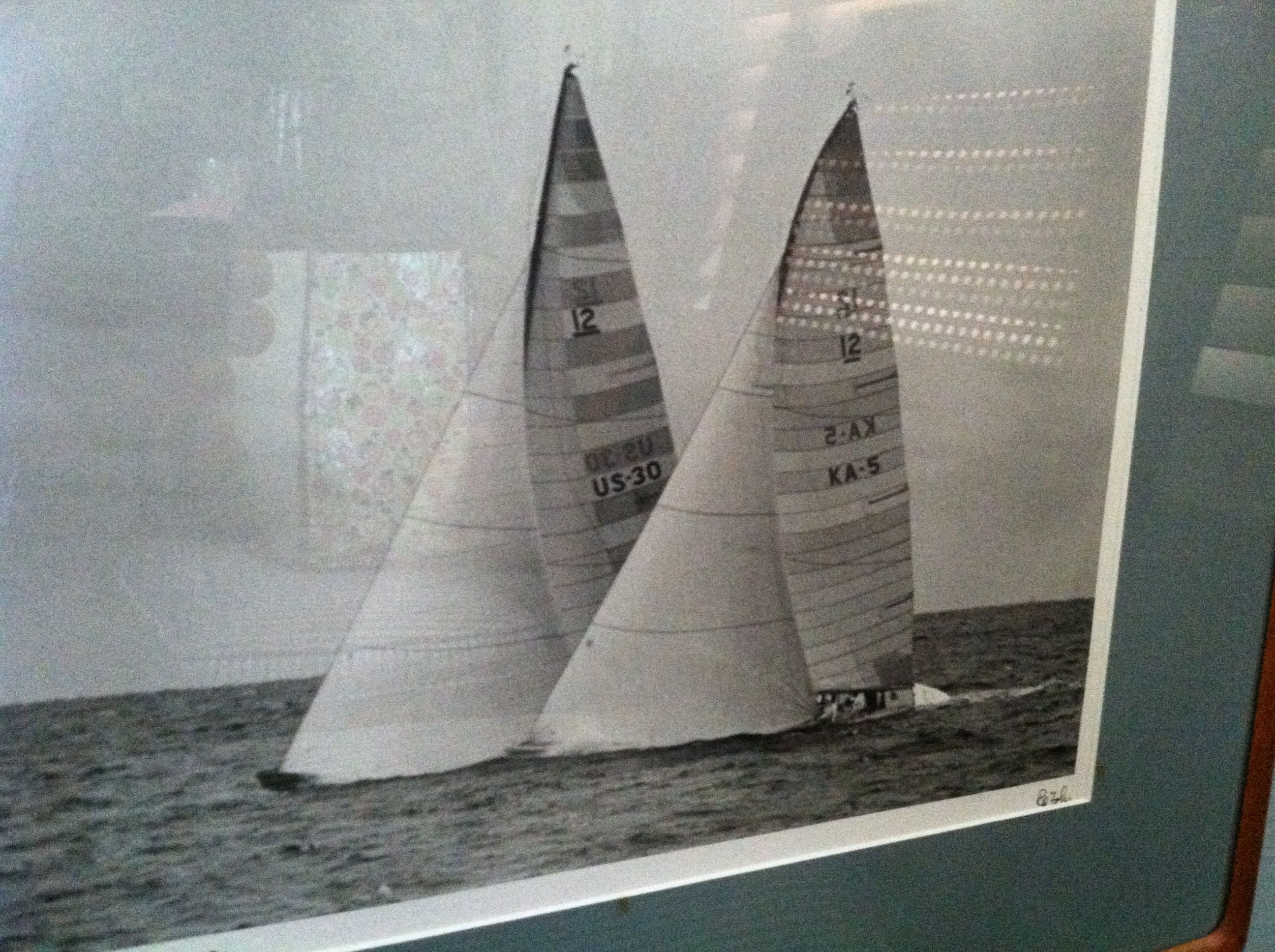

With respect to the sentence in the fellows remarks above, on “demand”, sailmakers (and cloth guys too) are forever trying to do something that will set them apart from other sailmakers. Battens, full and leech, for in-mast furling sails is a classic example of this. I am pretty sure that a Hood Franchise in Sweden invented both the batten idea and the necessary mechanics and sail designs to make it all work. Hood in the US marketed them as Vertech Mainsails and promoted, as does every one, the idea of more roach as opposed to the standard battenless sto-main with leech hollow, like a headsail.

Very broadly speaking, as viewed from my perch at Hood Sails for 15 years, there has been since the 1980’s an increase in people coming to sailing who did not grow up with it and so have a different seamanship background than say my generation who was sailing from age naught. Thus people buying boats (as well as a lot of others) were attracted to the idea of doing everything from the cockpit, so the in-mast furler’s, are now more common again than for a while. Without doubt the ability to “get the sail out and be sailing in one minute” or variations on same are pitch’s that do not quite fill the air at boat shows but is close.

Remember though there are two primary differences between the present in-mast spars and the original Hood Spars and they are the internal diameter of the cavity-Where the sail rolls up and the width of the slot through which the sail enters and leaves this cavity.

For all sorts of reasons the newer masts are smaller on the inside and the slot is much narrower than a Hood spar. Since the customer has a specific boat with a specific mast sailmakers are obliged to come up with ways of making their sails fit what the owner has, at a price they can sell them for while making money and having them work with sufficient success that the owner can use it, maybe enjoy it and so may return for other sails.

So, to the sails:

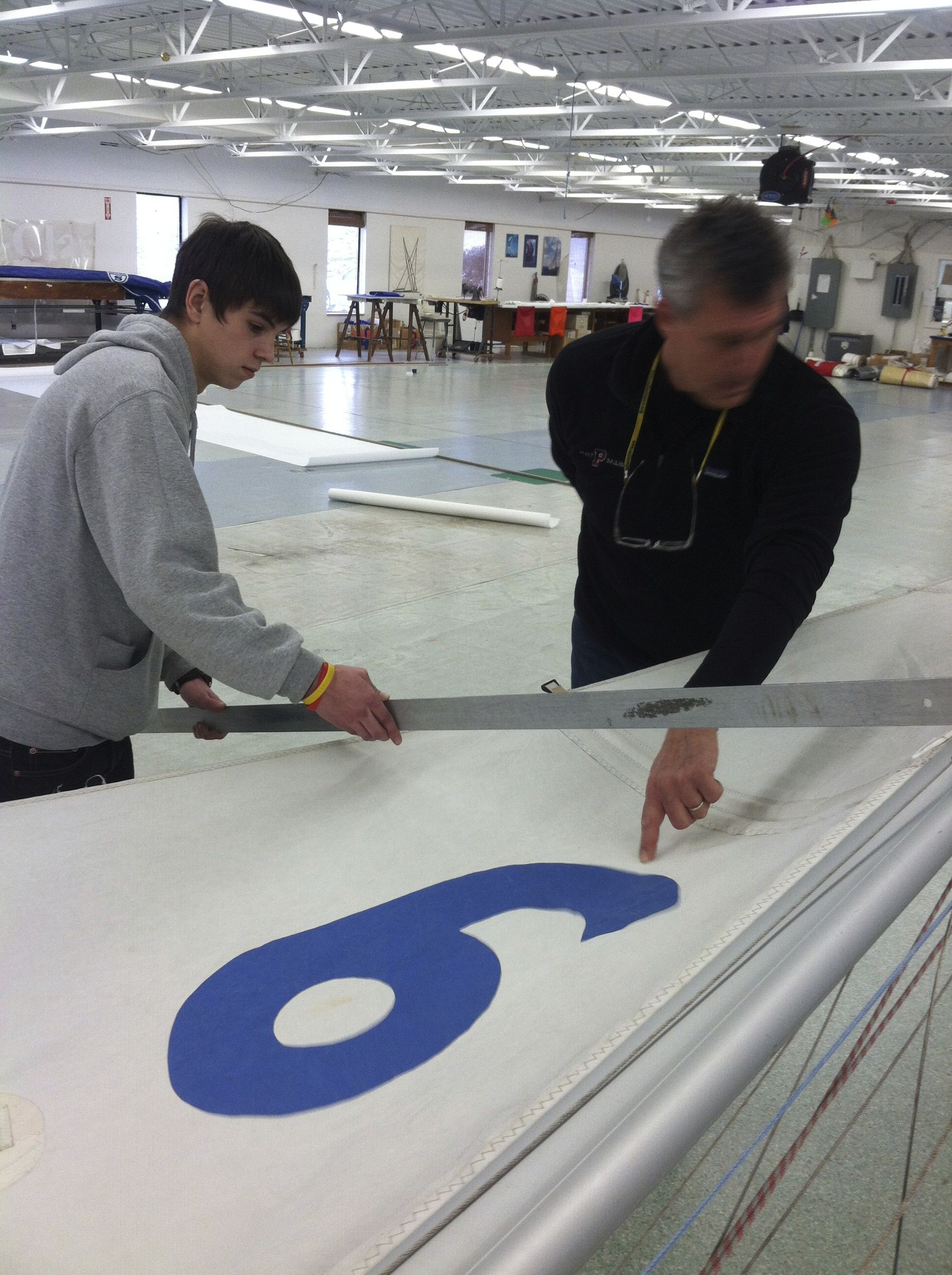

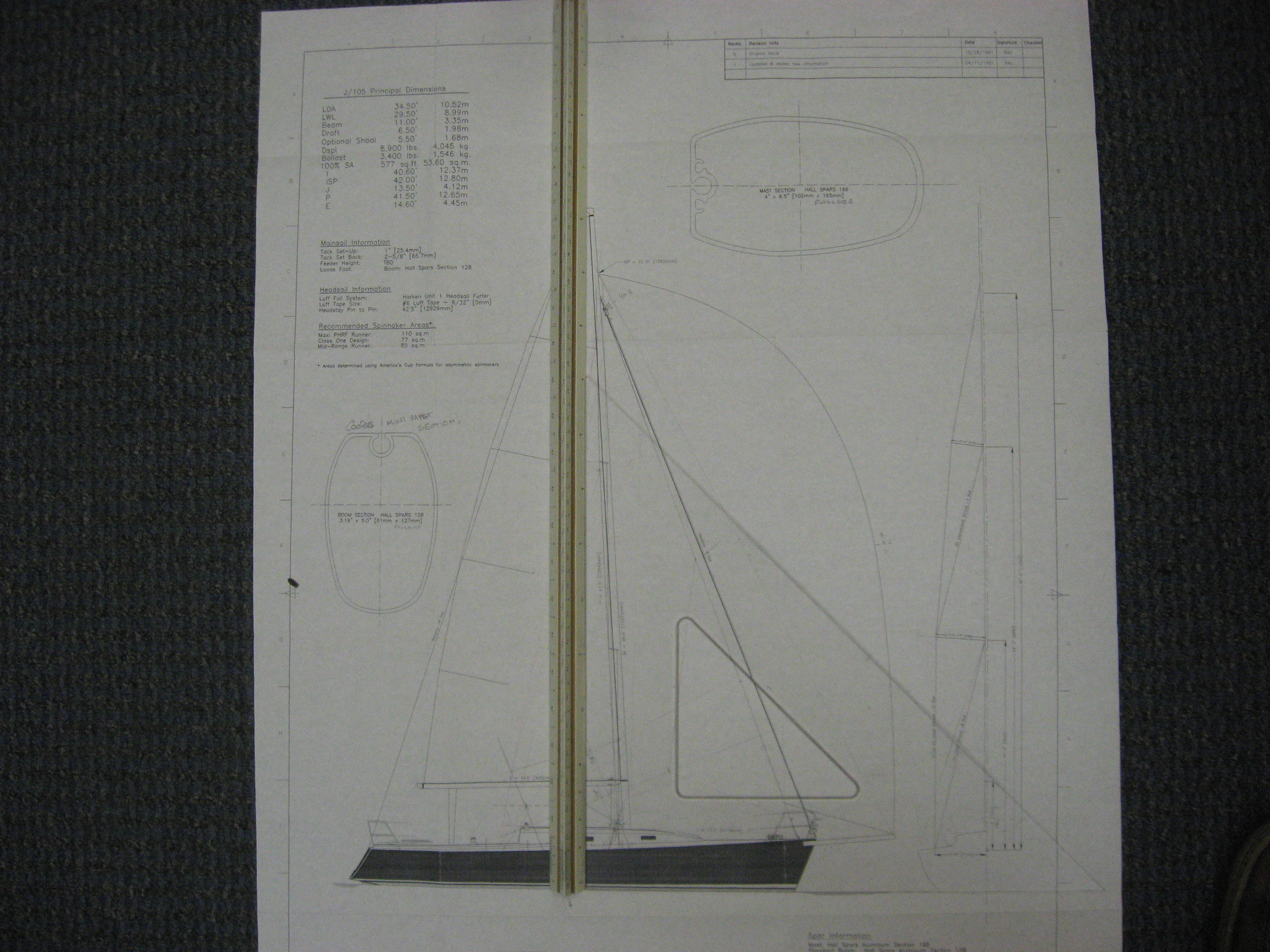

There are three flavors of in-mast furling mainsails: No battens, partial battens and full length battens. The latter are inserted vertically into the sail from the foot. These battens are usually in sections so they can be connected in some way. The ones we used at Hood, screwed together with custom fabricated terminals. The length of the sections, at least in the US, is determined by the maximum length UPS will carry so they can be shipped economically compared to shipping”regular” of FLB by truck.

With regard to sails, we know that the corners of a sail are reinforced with layers of fabric, the so called corner patches. The bigger the sail the larger, in area, are the patches. They are also thicker-more layers of material laid into the corner. This latter issue has a direct impact on the process of getting the sail in and out of the spar. The short answer is that for the current range of production spars the patches need to be thinner than they should be. This has a direct impact on the life, the shape retention life, of a sail because the corners distribute the loads into the body of the sail, less distribution surface, more load.

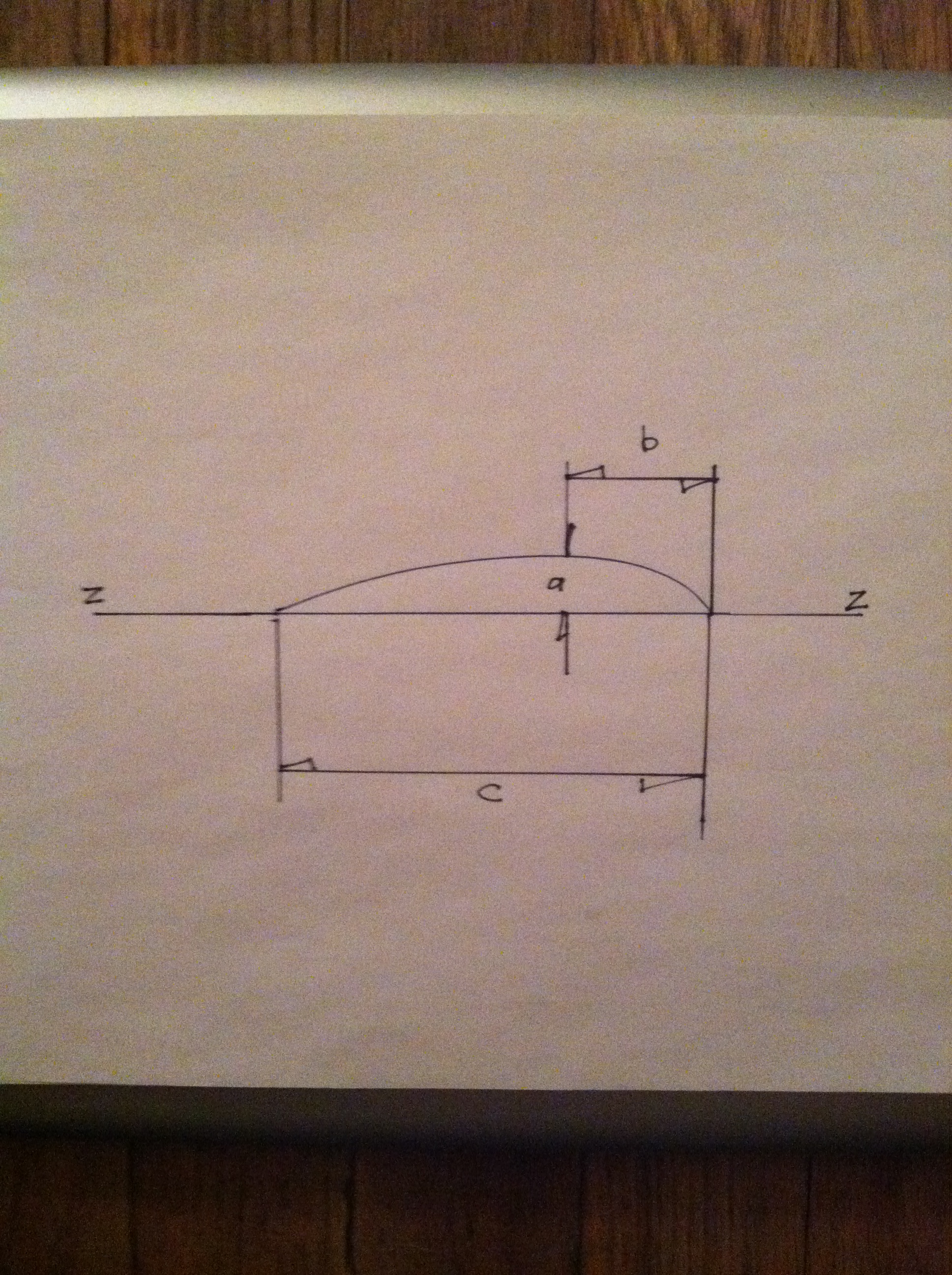

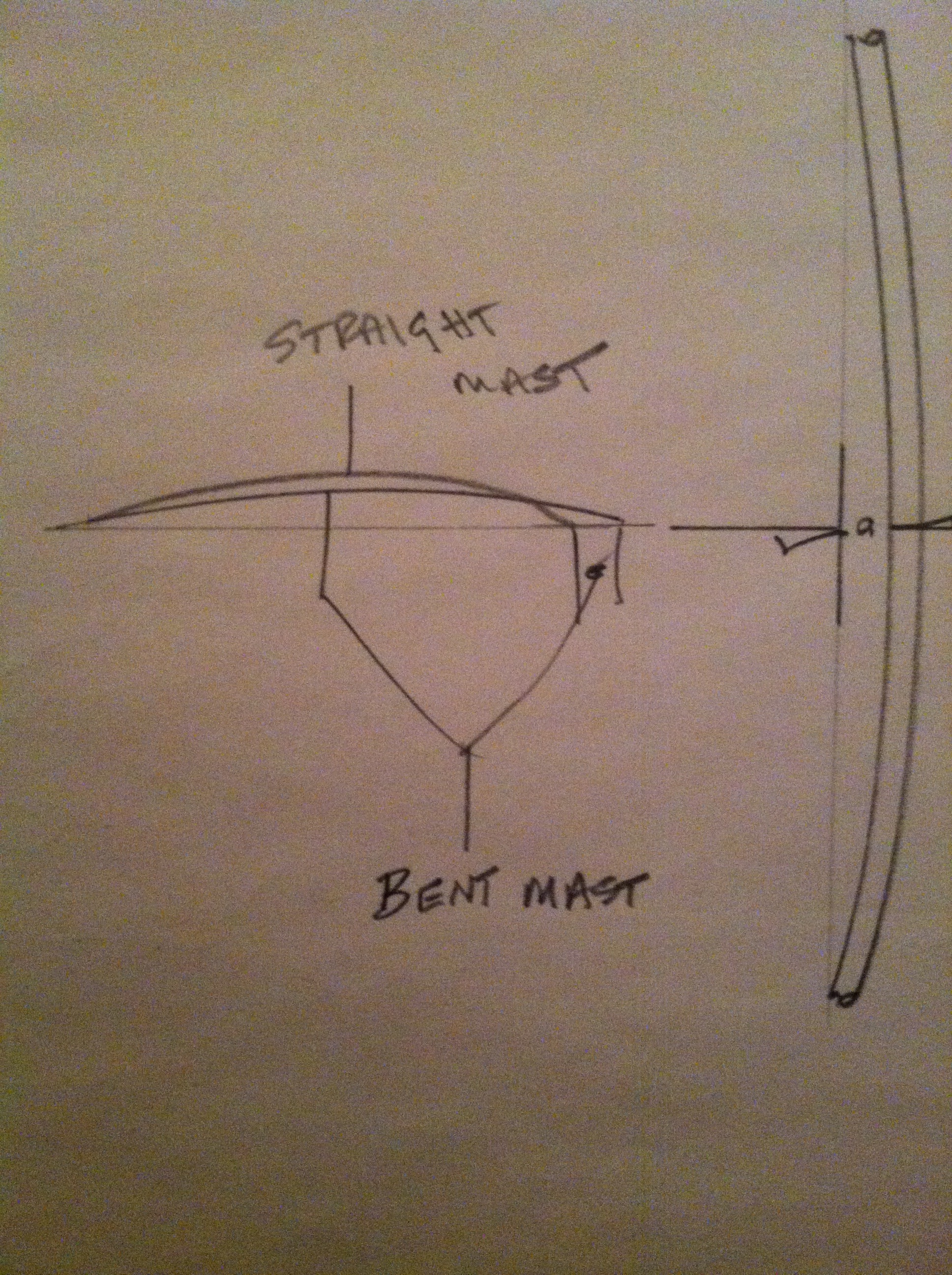

This thickness issues plays out with battens too. Let me first mention a couple of points about battens. As a general rule a batten’s length ought to be long enough so that 1/3 is “outside” the straight line between head and clew and 2/3 are inside. So the “inner” 2/3 is holding the outer third in place. This gets to be more critical the larger the roach-Hence full length battens in the first place.

This batten length calculus is relatively easy to meet in a conventional mainsail. It becomes a bit trickier with an in-mast sail. This is because when the batten is vertical, the batten needs to be a lot longer overall, in order to meet the desired ratio of batten inside versus outside the straight line. When the batten is longer it needs to be stiffer to achieve the desired effect. Given a same material, say polyester fiberglass, a pretty common material for battens, then a stiffer batten is thicker than a batten doing the same job on a conventional sail which will be shorter.

Still with me?

Then there is the batten pocket: It adds thickness to the sail. Typically the batten pocket is a couple of layers of material of the same weight as the sail’s cloth. The pocket has a pleat in it so the there is volume inside the pocket to accept the batten and there is some kind of mechanism to keep the batten in the sail. Velcro is a favorite these days as are folded over flaps with lashings as well. This construction is often as thick, or thicker, than the corners AND it is on the leech so all the battens, all four or five of them must be able to roll inside the mast….

All of the above is of course at reasonable hazard of chafe. The pockets where they go in and out of the slot. The sail skin itself is liable to chafe when being rolled in or out in any condition apart from head to wind. The chafe issue applies to all flavors of in-mast furling sails: plain or with battens. On the full battens, where the connections are, they are a tad wider than the neighboring batten material so when the sail is passing the edges of the slot, there is chafe at each of the perhaps dozen or so connections.

Re-read the remark in the original question above where the owner had to have the top batten removed so the sail would get into the spar. This means I hope that the attending sailmaker had to re-fair the leech too otherwise the “local roach” at that batten would either wave around in the wind or be pulled into a curl by the leech line. Any way I digress…

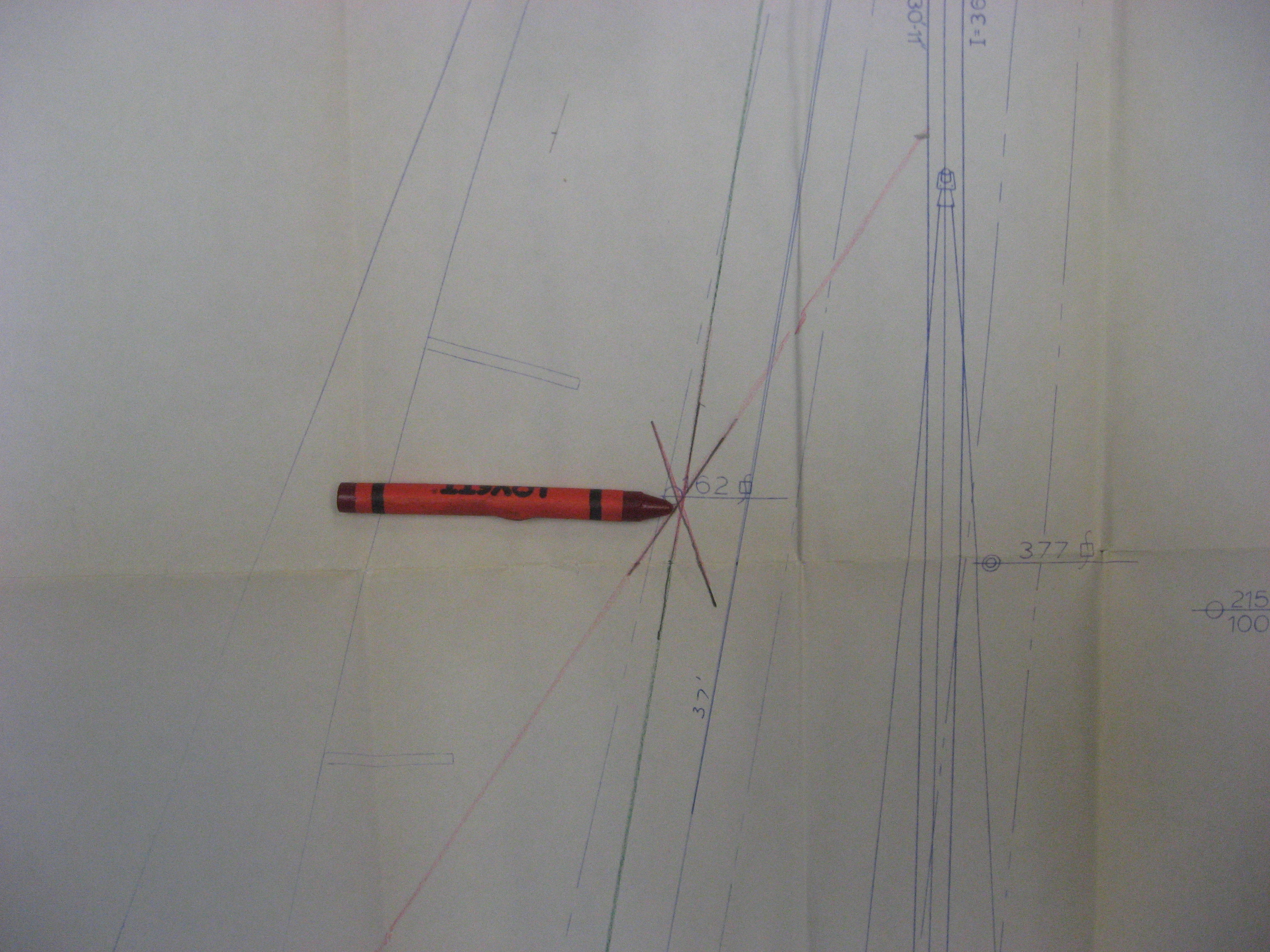

Now connect the particulars of a sail so designed and built with the newer masts with smaller cavities and narrow slots. The end result is that sailmakers need to make the sails “thinner” in order to fit into the spar. Plus the batten’s are thicker and there is added thickness for the batten pocket assembly.On more than one occasion a prospect was unable to purchase a battened in-mast sail for his boat, at least from us, because when I looked into the particulars of the mast he had and the boat (so I could spec. the sail appropriately) comparing the width of the slot to the thickness of the battens and related structure, there was barely enough wiggle room and this was without the sail skin or the pockets. I can recall one spar I was looking at, from one of three makers cited above and the slot was quoted as being only 16 mm wide, perhaps 9/16″. The battens, the pocket and sail was close to 12 or 13 mm.

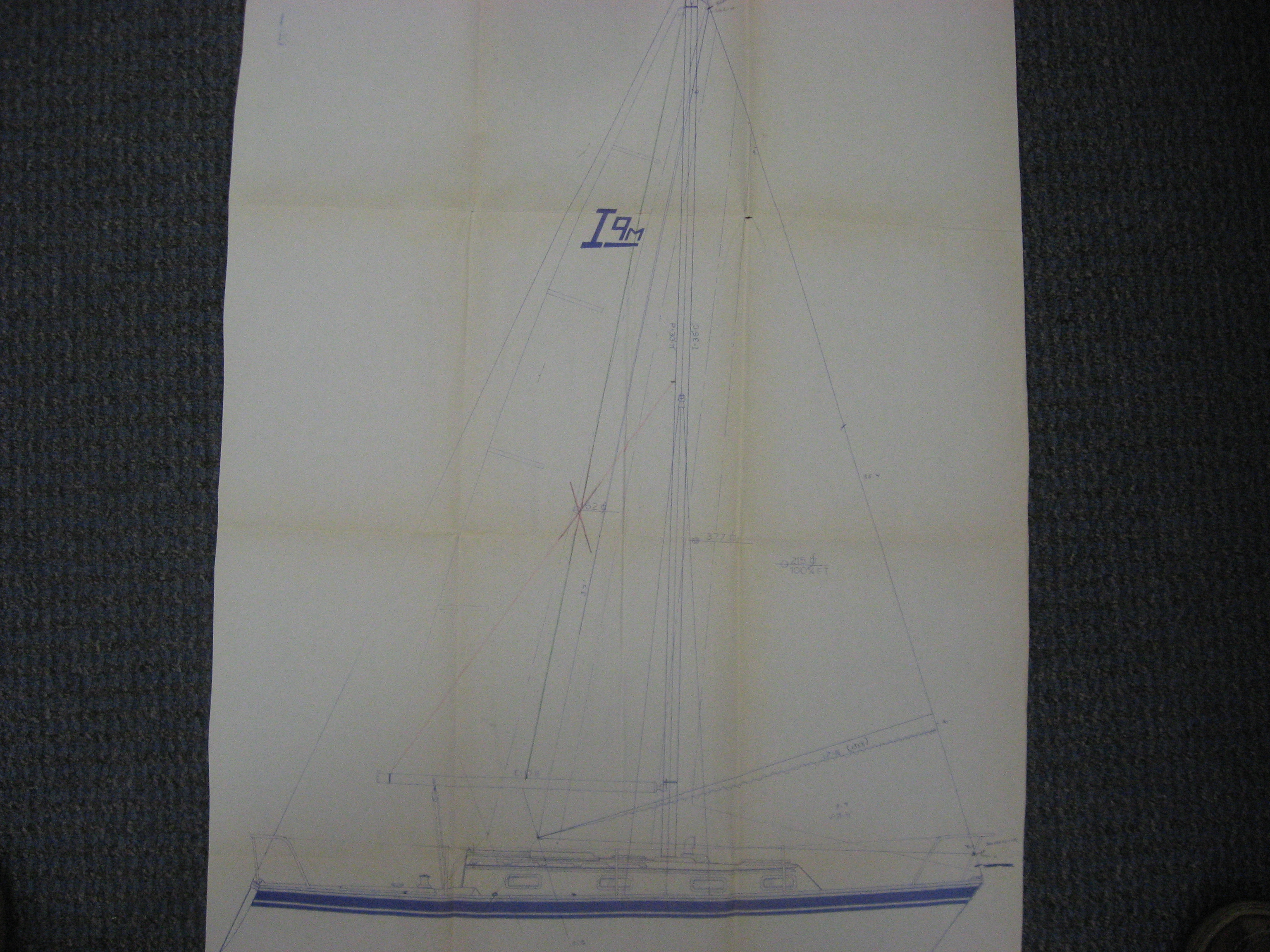

The same problems or issues occur too with full length vertical battens only there is the additional complication of having to install the battens in the sail with the sail fully unrolled. Think about this for a minute…Would you willingly unroll (or hoist) your mainsail at the dock in the marina and let it flap around for the time it took to get the battens in? Perhaps not. This drill is required though with the full length battens in order to get the batten (s) into the sail. For instance on a Little Harbor 46 footer with in fact a Hood Spar, so it was actually pretty easy to operate the sail once the battens were in the sail, it would take me 45 minutes to an hour to assemble the battens get the sail into the spar and the battens into the sail. And it could only be done either on a calm morning or with only a light air wafting across the boat from the direction in which the bow was pointed.

All of this would make one think that the in mast furling system is not possible to manufacture and sell which is patented not the case. Rather I am presenting some of the issues that go on behind the curtain. For the sail these are:

Thinner or lighter base material, smaller patching both in area and in total weight in the patch and thinner battens and/ or pockets.

So, I hope this has offered some food for thought as well as a bit of a glance around “behind the curtain” into what goes on in the minds of, and discussions of, sail makers, their reps and designers.

I’ll get back to “regular” full length battens-soon.