With apologies to you know who.

I have received another question and a related comment from some readers on the LinkedIn forum “Sailing Network”. This forum requires authorization but the access is free once registered.

The question comes from Pippa who appears to be either the principal or a partner and is a RYA Yachtmaster Instructor (Sail) with Miramar Sailing School, Antigua

“I’ve been reading your comments and blog about Fully Battened Mainsails – I have a Jeanneau Sun Odyssey 40 which has sails that are probably the originals from 1996. The main is starting to look ‘tired’ and we have been considering getting a new sail with only leech battens – do you think this would be a retrograde step, or not make a significant difference to her performance? Obviously the current main being a bit out of shape won’t help, but will we regret not getting a replacement that is fully battened? Interested in your opinions!”

This is the comment from the same forum from a reader in San Francisco, DG Tilton-

“Get the full battens. I got about half a knot better in low winds. Most importantly, for students, better control in a jibe. The extra expense of new batten cars/slides for the mast was well worth the investment. The command of out haul for shape also improved performance as well. The difference between old and new is always an increase in speed. But the performance of my sail in 12 years is like new. I teach heavy weather sailing in SF Bay. Our typical winds of 25 kts to 35kt present dynamic conditions due to micro cells of wind vortex. Your lighter winds in Antigua make sail shape even more important. The difference is like releasing more energy for speed instead of drag.”

This is interesting because both correspondents seem to be in the sailing instruction business and both seem to sail in conditions of more than enough wind, most of the time.

I will point out here I am not writing to advocate for or against full battens. Each boat, owner, situation, skill and experience level, sailing plans and a sea-bag full of other factors influence any decision on a boat and the decision on FLB’s is no different.

These essays are to share what I have learned over a more than 15 years as a sailmaker sales rep. that is incorporated into over 50 years of sailing including roughly 40 in the marine trade.

As I read through the question and comment i received, I have the following questions for Pippa centered on her basic question to me:

Would getting a sail with FLB be a retrograde step OR make a significant difference to her performance?

Then the first thing is to go back to the first essay and review the discussion there in particular the part about performance increases after either:

Adding FLB to an old sail. Second is getting a NEW sail with FLB.

My question at the beginning of the first essay is:

Can the “increased performance” be attributed to the Full Battens, on the new sail

OR

Does the “increased performance” stem from the fact that the sail is new and so has all the advantages of a new sail?

These include of course a new(er) shape, perhaps “better” (more stretch resistant-even Dacron) materials than the old one, perhaps larger area via more roach, I note that OEM sails are notoriously “small” with regard to roach and the materials used in such sails are not so great, a superior shape design if from a different sailmakeing firm and or designer or simply what has been learned over the intervening years since that sail was designed.

I am not aware of truly empirical evidence that full length battens on THE SAME SAIL, ON THE SAME (class of) BOAT improve the PERFORMANCE of the boat. And how are we defining performance? Faster, higher or both?

Issues to consider when trying to answer that question include:

- Does a FLB mainsail make the boat so equipped sail faster and or higher-compared to the “old” sail with out FLB?.

- In what wind speed?

- In what sea conditions,

- Steered by whom?

- With or without a prepared and smooth bottom?

- With the same amount of stuff, in the same place in the interior?

- With the same headsail, in the same “shape” condition as when the old main was being used?

- Same rig setting?, rake, backstay, mast prebend cap shroud tension?

- Same weight on the rail?

- Same helmsman?

These all play a part in a boat’s “performance” and are some of the particulars that sailmakers want to have in place before even consenting to go on a sail speed trial. Organizing and executing such testing with two boats is a right royal tedious business too,even at the top end of the sport and is full lots of small details that are very hard to uncover. For instance I once did a sail for a fellow with a free standing cat rig spar. After delivery he called to complain that he could not keep up with some of the boats at the rally/rendezvous he was attending. After about 6 hours of sailing, questioning, measuring, reviewing details of the design, I discovered that this fellow had a mast step that was in totally different place than other boats I had measured on the dock adjacent to him and that his spar was, for reasons unknown it was larger in diameter…..He did not even know it was larger.

I can attest from my own experiences that determining if one sail is faster (and or higher) than another is a very long drawn out process. This experience comes from two America’s Cup campaigns and lots of hours sailing along in a straight line with lots of smart and experienced sailors and sailmakers trying to make the boat go as fast as it can, then changing nothing else except the sail in question and repeating.

Thus even with an identical Sun Odyssey prepared as closely as possible to Pippa’s boat in order to be as equal when sailing along side each other; there are still many variables to be incorporated before the “increased performance” of the sail can be attributed to the sail having Full Length Battens.

Read again my remarks in an earlier post as to why,” if FLB are faster”, why then does the J105 class not all have FLB mainsails for instance? The 105’s have no rules regarding batten length. The paragraph is about half way down the post.

The next part of a decision to incorporate FLB into a new sail has to do with, as I wrote in the first essay, value and encompasses things like:

- Extra cost for the (addition of the) battens on the sail.

- Issues of moving FLB around by carrier if necessary. Long, and skinny is expensive to ship even if it light in weight. I am thinking, Spares.

- What are you going to use for luff hardware, at what cost and thus value? In my going for the cheaper option is not sound. This is especially so on a 40 footer, used (I am assuming) as an instruction boat with the attendant minimal seamanship (as distinct from hours or miles of sailing) experience of the students, one assumes, in an area with more than enough wind most of the time.

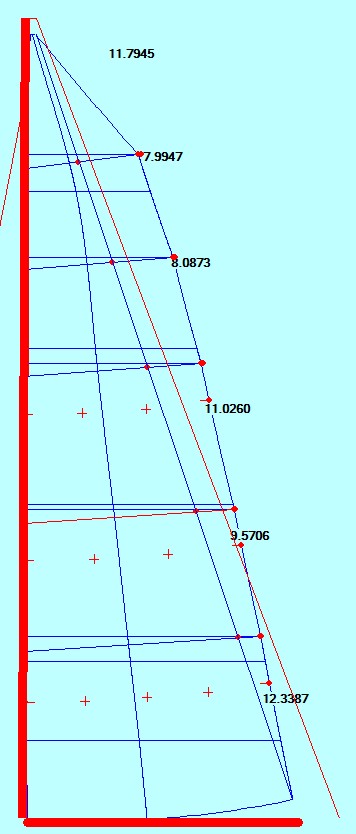

- Considerations of maintenance, specifically chafe: The Sun Odyssey 40 has spreaders with some amount of sweep to them. When running down wind the battens, especially the top couple will bear on the standing rigging and chafe due to the hard spot where battens in the sail cross the standing rigging. The chafe will be harder than a sail with conventional battens.

- The mechanism for securing the sails into the pockets-Perhaps not a great issue on a boat that may not stray far from home. Regardless reefing any sailing 25-30 knots of wind always flogs the sail and invites battens to spear out the leech end.

- Stowing the sail on the boom. Here is one area that the FLB are or can be superior and perhaps add the value but only if combined with a slippery track arrangement and some kind of sail containment. The SO 40’s I looked at on the web all have some kind of boom bag and lazy jacks for the sail to be captured by and stowed in. Again more money.

- The battens and pockets, cars and batten boxes all add weight. I have memories of a mainsail for a 40 footer weighting 50-60 lbs. Add another 15 pounds for all “the stuff” if the sail has a really low friction track and car system.

- The added weight of the track and the now heavier sail all sticking up in the air will have an effect of some magnitude on the boats stability. Whether or not it is visible to the human eye depends on other variables.

I am not going to recommend or not FLB. As I say above my goal is to lay out what I see as the issues that by experience many folks do not consider in their interest in and experience with FLB.

In sum the question for Pippa to contemplate is:

“Is all this worth the extra capital cost and the maintenance cost compared to the Value you get from them?”

Value being subjective but of course including performance (it will be a new sail after all), possible increase in ease of handling the sail-if appropriate sail capture kit is incorporated into the boat, additional weight to hoist, a less “aggressive” flogging” of the sail when it is not trimmed. This is because the battens slow up the frequency of the individual flaps, to and fro that are the components parts of flogging.

Pippa, you asked for my opinion, well here it is (grins) Mr. Tilton says that the “extra cost” is worth it but that is a decision you will have to make for yourself and your own circumstances.

Were I consulting with Pippa on this sail in my previous life, these would be the questions I would be putting to her.