One of the things that gives most sailmakers gray hair is confirming the dimensions and details of fit for the sails they make. This selection of articles discusses the things sailmakers need to know and what the definitions are so the consumer can provide the correct information. There is nothing worse than getting down to the boat on that lovely Spring Saturday morning with the new sail only to find out the luff slides just don’t quite fit the track. Read on to find out how to help eliminate such frustrations.

Virtually all boats have their “rig plan” defined by four dimensions. These are called the I, the J, the P, and the E. The I & J define the headsail and the P & E the mainsails. There are some other subcategories but let’s start with these four first and we will start with the mainsail and what the P & E dimensions are NOT.

- The P is NOT the luff length of the actual sail.

- And it is NOT the maximum available hoist on the mast.

- The P dimension is NOT anything but this:

The distance up the mast (from the top of the boom) that the designer has calculated as the maximum luff length that a sailmaker might build a sail to (which, in conjunction with the other dimensions, I, J, E) will give the boat the sail area the designer wants it to have.

In plain English, “P” is in the first place a mathematical construct. In practice on most boats, especially those sold with “racer” in the name, the P is measured “from the UPPER edge of a contrasting color band at the gooseneck UP to the LOWER edge of a contrasting color band at the mast head.” This (is an approximate, but close) quote taken from most sail boat rating handicapping rules, like for instance PHRF, IRC and ORR. Any class or make of boat that desires to limit or control the mainsail area will make some definition similar to this. An example of what this (commonly called the black band for obvious reasons) looks like is this on a Hallberg Rassey 31 footer.

The Black Band is located at the tack and P dimensions are taken from the top of the band to the underside of a similar band near the masthead.

Now the observant amongst you will say, “But the tack of the sail is a couple of inches above the upper edge of the black band!” Go to the top of the class- this is the nub of this article. That detail is called the tack set up and we will get to that detail. Another version of the black band is here.

And if the mast is black-Carbon or anodized-the band is white.

This “contrasting colored band” is at the gooseneck (so the lower) end of the P dimension.

The top end is of course at the masthead, more or less. There are a few variables related to the positioning of the Upper Band of P. One fairly important one is the length of the backstay crane. This is the structure at the top of the mast to which the backstay is attached. The design and installation of the backstay crane varies over time and boat design and intended use. In the case of older boats, and in particular boats with wooden masts, there is for practical purposes no backstay crane. So backstay crane’s come in all manner of configurations. The one of most interest to the sail makers is the length, I.E. the extent to which the crane and in particular, the attachment of the backstay to the crane is aft of the aft face of the mast.

The detail I am thinking about when measuring this boat is making sure the sail does not foul the backstay when set to full hoist.

1. The height (length) of the luff of the mainsail is determined first by knowing the boat’s “P” dimension.

On many boats, especially “cruising” boats, like this Alajuela 33 pictured above there is no black band. Quite often the P is determined by consultation with any of the various compendiums of sail boat data sailmakers have at their disposal.The sailmakers must ensure that the mainsail headboard will not foul the backstay when the sail is at full hoist. The sail in the picture is actually at the “correct” height for the boat’s stated “P” dimensions (even though it looks “short”). This was confirmed, (reconciled really with data I had researched on the class of boat) in advance of the new sail being made by measurement (by me) of the spar. If on the other hand the sail was built to full hoist, right up underneath the crane, it is most likely that the headboard would foul the backstay.

TIP: measure the spar fore and aft at your eyeball level standing on deck. Then eyeball the crane and visualize how long the crane is compared to the spar thickness. So if you reckon the mast is 8 inches long, fore and aft, and the crane is about 50% of the size of the spar, then a good estimate is the crane is 4″.

In this image, below, of an older wooden spar, there is no crane and no black band. Fortunately there is no backstay either. The line passing through the block is the topping lift.

2. The size (how long fore and aft) of the headboard and so how far aft the corner of the headboard may extend (including with all the luff hardware attached) aft of the aft face of the spar. The sail pictured below has a special headboard included with this luff hardware. On this boat the entire sail is about 1.5 inches further aft from the mast than it would be if the sail merely had “normal” slug slides.

3. The position of the backstay attachment to the crane.

On some racing oriented boats, like this Pearson Flyer, pictured below, the “P” is literally at the bottom of the main halyard sheave. Indicated in this instance with a white band on the blue spar. The crane is fairly long, for a 30 foot boat. The backstay is led through a, so called, “backstay flicker”, so that in light air the backstay can be eased to let the roach of the sail pass thru. Refer to more information on this in the Full Batten posts.

This absence of backstay crane is the main reason why there is often upwards of 18″ difference between the upper P measurement point and the “top of the mast” as is seen, below, on this wooden mast.

When you lower your old mainsail examine the anodized aluminum headboard for scarring on the after corner and if it is so marked almost for sure the sail has stretched to the point where it is fouling the backstay.

On some boats there is a backstay crane yet the band is still a ways down from the “max hoist” distance, as here.

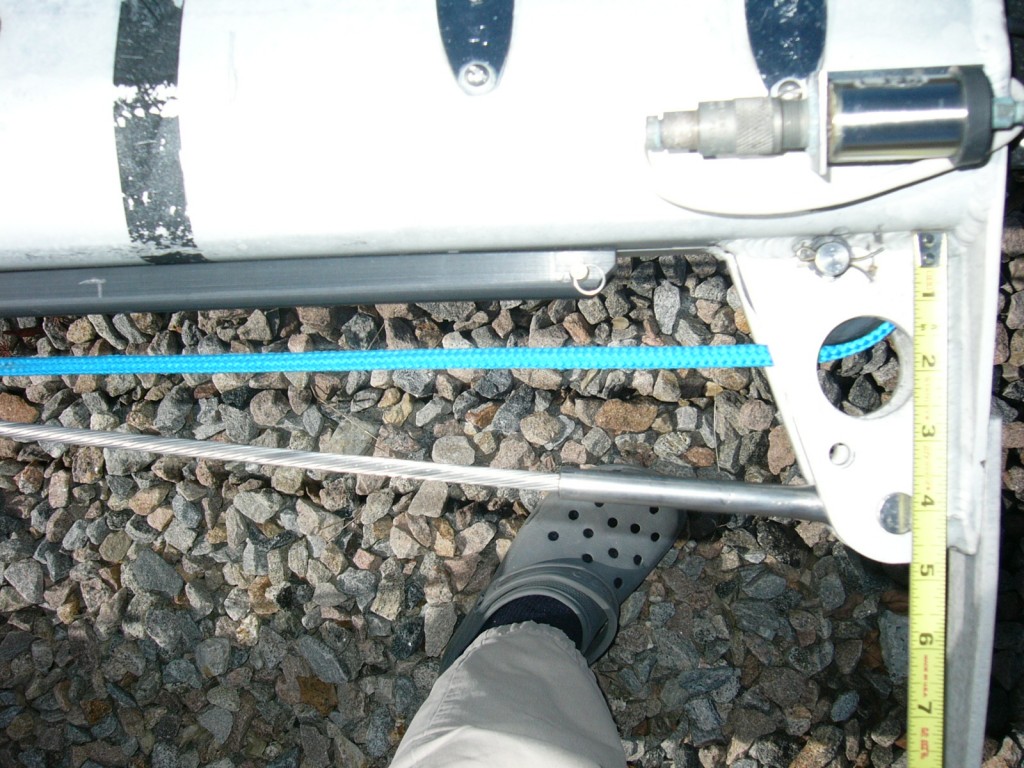

You will observe that in this picture I am measuring the backstay crane so as to make sure what even headboard we select it will clear the backstay. How we figure that angle will be discussed in greater detail further on in this series, but basically we take a dimension from the gooseneck aft to where the backstay passes the end of the boom.

A common default measurement sailmakers use for determining the size of the headboard, stems from racing rules and that is 4% of the boats E dimension. So for a boat with a 12 foot E, then the default headboard would be 5.76, or basically a 6 inch headboard. Unless the boat is racing, and this is a detail of the transaction though the headboard would be shorter, for all the reasons discussed above.

So, to recap, the “P” is “the distance between the top of the lower band and the bottom of the upper band.”

It is not the luff length, the max hoist or anything else.

The “P” dimension and the “E” dimension, discussed in the next article, are the two pieces of information the sail maker will need to have to even begin to think about figuring out all the things he needs to consult with you on a new sail. Subsequent articles will discuss the detailing at the corners, tack set back, tack set up, reef set back and clew set up battens roach and a few other details pertinent to buying a new mainsail.