Regular readers will know of my enthusiasm for Solent stays as a great “Gear Change” for most conventional sailing boats. The Solent is particularly effective if the boat in question has a low aspect-ratio rig. That is the height divided by the J-this distance is roughly the forward side of mast at deck level forward to the head-stay fitting on the deck. So for instance a spar height (commonly referred to by riggers, mast makers & sailmakers as the “I”) of say 45 feet and a J of 15, is a three: one aspect ratio. A boat with a 47’ x 12’ rig is close to 4:1 aspect ratio.

And yes a tall skinny sail is just fine more or less—When sailing up wind close hauled—Only. For the average cruising boat high aspect-ratio sails are not so good. This has to do with both the strain on the head of the sail: the top of the sail tends to go very round in the head pretty quickly and more importantly, when the sheet is eased, the top of the sail twists off dramatically. When adding foresails to the inventory, an owner would be well advised to consider the aspect ratio of the where the sail is to set.

Quest 30 arriving in Newport. Headsail in use is the primary sail on the furler. You can see that the sail is relatively tall and skinny

With this in mind I have been working on just such a problem over the past month or so. A mate of mine is preparing his Quest 30 for the Bermuda 1-2—a solo race to Bermuda from Newport, RI then a DH race back from Bermuda to Newport. The Quest has an “I” of 41.0 feet and a “J” of 10.7 feet so again close to 4:1. Since the boat is to be sailing the ocean, simply relying on only one headsail on the furler to sail across the most likely spectrum of winds between Newport and Bermuda in June is not a sound seaman like option. Especially with this type of furler which is merely a furler, not a reefing headstay.

The boat does not readily allow of a Solent set up, in the classic fashion–Roughly parallel to the headstay and a foot aft. Thus I had to design a system for setting a small sail that ended up being a Solent hybrid. A cross between a “cutter” stay and a Solent. In this case the bottom of the stay lands very close to the stem head of the boat, like a Solent stay would. BUT the top of the stay lands at the second (top) spreader in the way a conventional Cutter stay might. There are a few reasons for this.

Primarily the fact that the spar had already the fittings necessary for a stay, runners, a sheave box and the halyard all at the top spreader-See image above.

So there were a lot of the basics for a stay on which a small sail could be set, with out re-designing the entire mast and deck layout. Overall my goal was:

- Design a system that could be deployed easily quickly and with the least amount of ruckus given that when it is going to be used, it will be blowing at least 25 kts.

- Ideally the installation made use of the various equipment already installed and available on the boat-We did not have time or inclination to get into the boat building business.

- Do it in a way that was cost effective, the more so since the entire staysail arrangement would only be rigged up on the spar and deck and perhaps not even deployed at all, every two years for the Bermuda 1-2. The rest of the time it will live in a bag in a locker somewhere.

- Get it all designed, fabricated, installed and sea trialed as soon as could be done so any adjustments could be done in a timely given the start of the B-12 is 08 June.

I know this boat, intimately as it turns out:(I sailed this boat to Plymouth, UK in April 1996 so the then owner could sail it back in the OSTAR-But that is another story) So my first question was to look at the rest of the sail inventory to discover what headsails were to be carried in the race?

- The primary headsail is a 105% or so slightly high clewed jib set on a roller.

- The mainsail has three reefs. The head of the mainsail is below the top spreader when the third reef is set-Watch for this detail later-on in this post.

- There is a small sail called a storm jib, but having used this sail on the boat, I know it is a useless in practice. It is the wrong geometry completely.

- The boat has water ballast. This is in effect another gear/reef. As the wind comes on, rather than reefing, filling the water tanks is the equivalent of reducing sail.

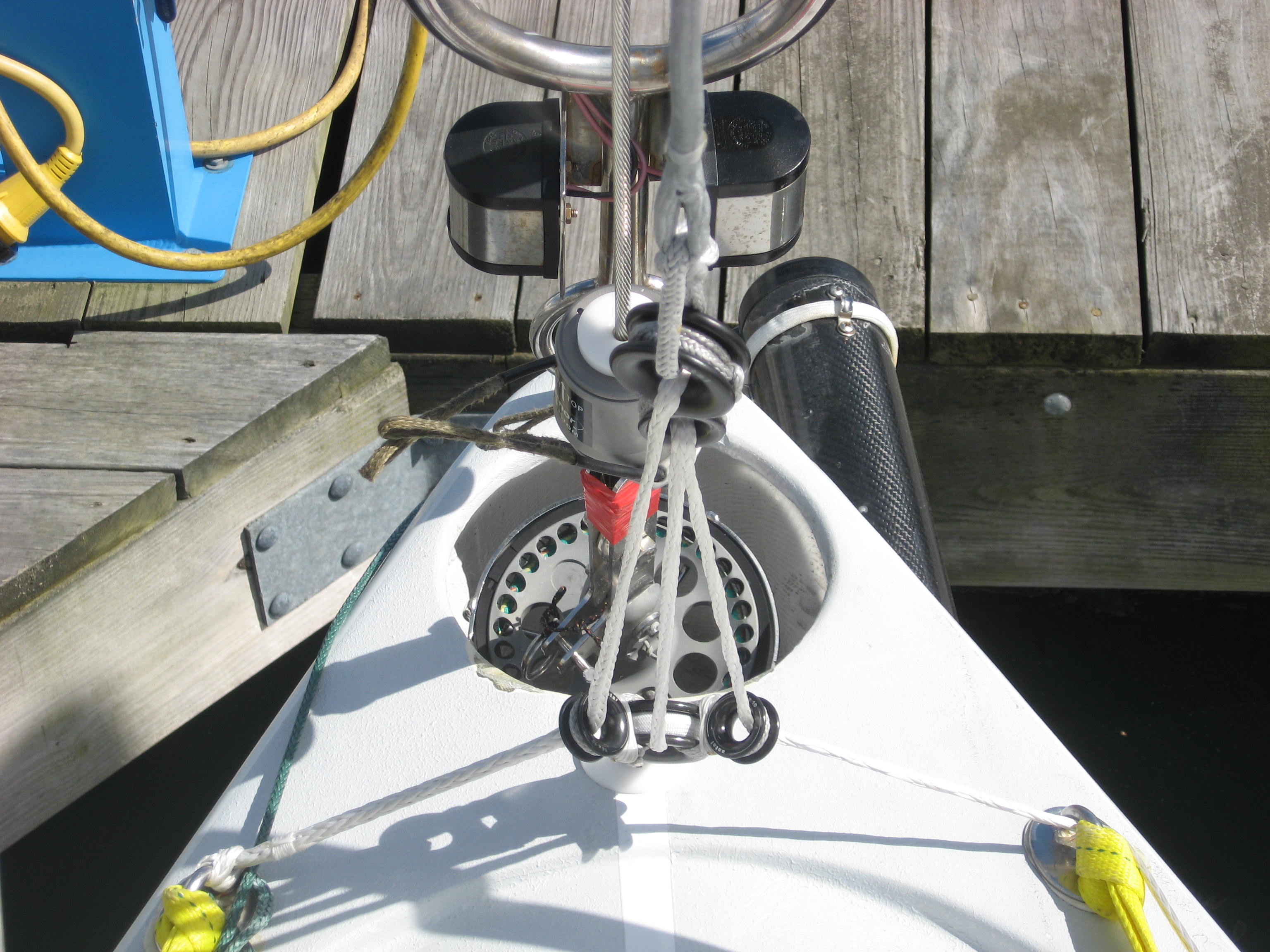

The primary 105% furling headsail sets on a furler at the stem head, like normal, but not on a “normal” Harken type furler with a foil. It sets on a Facnor 4500 foil-less furler. As the images below show, the furler is very simple:

There is a stay made from 1×19 wire as is pretty normal. The tack of the sail attaches to the drum–You can see the horizontal pin with the key ring and light line holding it to the boat in the above picture. The drum is driven by an endless loop line (led aft) that rotates the drum and so the wire: the head swivel rotates freely. The sail is attached to the stay by the soft hanks made of Velcro.

The idea here is to get the best of two worlds. A sail that can be furled, most of the time, BUT when it needs to be removed, it can be unrolled and lowered to the deck like a sail, with, well hanks-Just like the old days-So the sail is not going to blow all over the foredeck life lines and end up in the water.

The furler for the primary headsail is an foil-less furler. The Jib uses soft hanks connected over the wire stay. The grey cylinder is the top swivel

The white material aft of the drum attached to the tackle is a strop we fabricated to pass through the deck and connect to the headstay pin. To minimize chafe we installed a through-hull fitting into the deck for the strop to pass through. We attached a Wichard eye to the headstay pin and secured the strop to the eye with a soft shackle–The image seen below is a light line we used to line up the hole through the deck to the headstay pin.

To anchor the bottom end of the stay, we threaded an eye to the aft end of the pin holding the headstay to the boat. The light line is a guide we used to line up the angle of the stay through the deck with the eye fitting so we could get the right location in the deck for the stay strop to pass thru.

BUT

In practice I cannot see unrolling this sail lowering it, (the material is pretty stiff and the sail has vertical battens-as seen in the top picture sailing into Newport Harbor), lowering it to the deck, removing the battens, flaking the sail, getting it in a bag, releasing the hanks, pulling the tack pin out, un-shackling the head of the sail from the swivel, without losing the shackle, getting the whole show below without losing anything over board, including yourself, getting banged up yourself and then finally reversing the process with another small sail.

I cannot see that process talking less than an half an hour per sail even on a 30 footer.

So as a practical matter, the primary headsail would be furled up and a smaller sail set so the boat needed an inside stay.

A quick scan of the possibilities indicated that the best option would be to have a sail set from the top spreaders and landing just aft of the head-stay. Some of the issues to do with this that needed to be addressed included:

- The main furler is installed below decks in the anchor well, so immediately aft of the forestay, there is nothing meaty enough to land a stay on.

- Since the sail would go to the top spreaders, the rig would need running back-stays

- If the small sail was to be set on the foredeck, at the aft end of the anchor locker, then the aspect ratio would be too tall and skinny-Not good geometry for a hard air sail, to be used in the ocean. The aspect ration of this triangle is over 3.5:1-too tall and skinny.

This image shows the location of the one pad eye aft of the stem, at the aft end of the anchor locker. (far left of picture) This was unsuitable because to install the stay tensioning tackle properly would have needed another couple of pad eyes AND the sail would be too small AND not very good geometry–Too high aspect. The results of what we did-Install a tackle and stay just abaft the stem-head, can be seen in this image.

“Normally” inside stays for most cruising boats today (although I am apparently single-handedly changing this), of any flavor use some kind of mechanical ratchet crank device or a Hy-Field lever. Both of these options are:

Heavy, difficult to handle, very difficult to tension after a while when everything as stretched in, and being heavy are awkward to man-handle around the foredeck when needed. They cannot be removed in a hurry as circumstances dictate.

A Wichard hand crank adjuster on the Solent stay on a 44 footer, using a wire stay-This particular wire stay has been replaced by a textile stay that weights 5 pounds. Handling the crank, stay and a sail is way too much work and being heavy throws a lot of inertia around in the seaway that will be in evidence when this equipment is in use.

At the end of the day I designed a set up as follows:

Textile stay fabricated from a Spectra fiber product known to Hall Rigging, who made it for me, as Fiber wire.

The Fiber Wire stay. The keys are to give idea of scale. The “T” fitting is visible on the right hand side

This stay attached to the spar using a T fitting, seen above

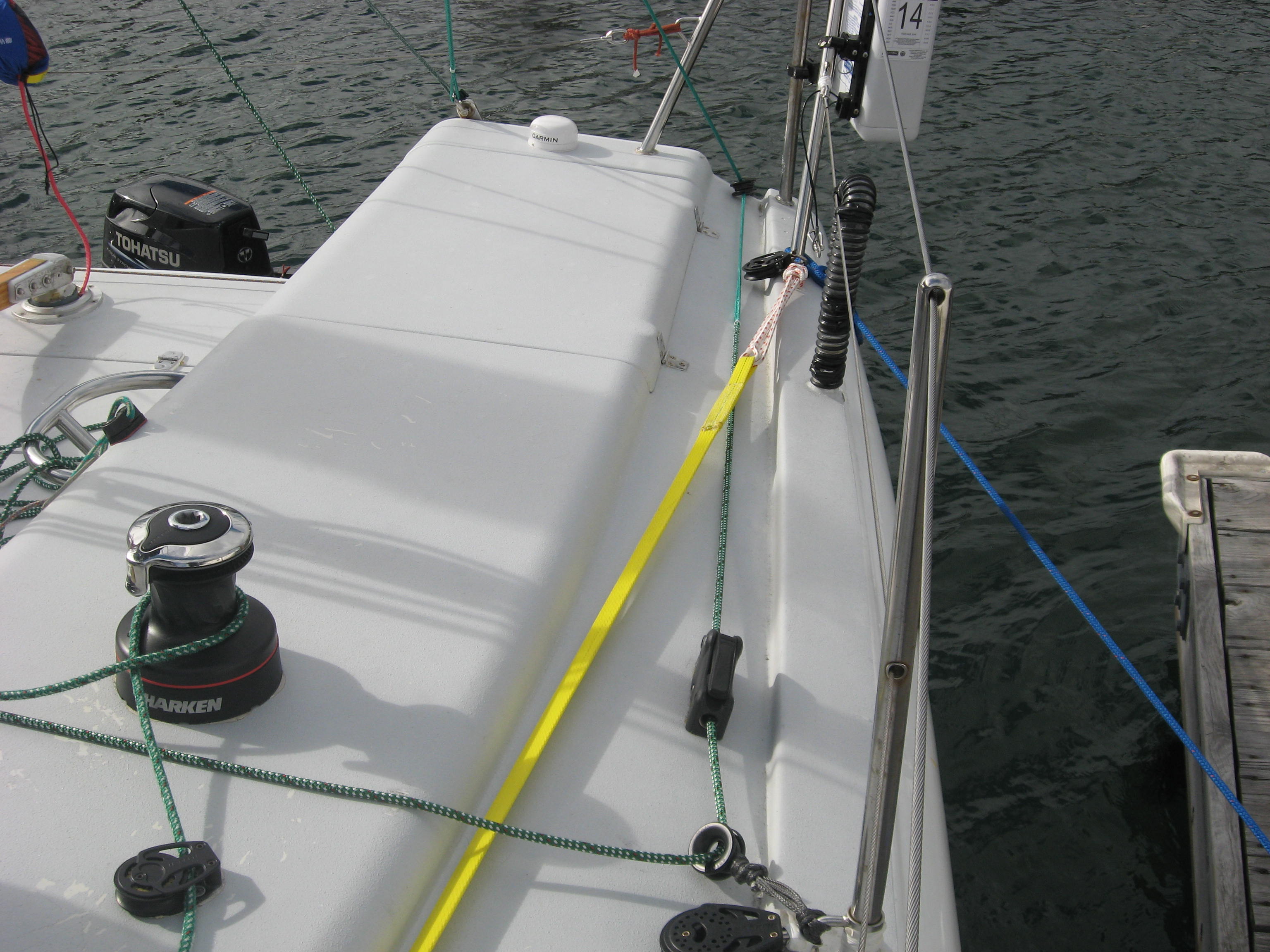

The bottom end of the stay was tensioned by a 4:1 tackle running through Antal thimbles.

The tensioning line is dead ended on the port side and runs aft, through the pad eye on the starboard side to a clutch in front of another Antal thimble and from there the tail is long enough to go to any winch.

The stay is tensioned by a 4:1 tackle running through Antal thimbles. Since the line is not required to be adjusted all the time, the thimbles are perfect. They are light, strong, in-expensive in general and particularly when compared to a ball bearing block of equal strength, the latter by perhaps a factor of 10:1.

The knobby ball of cordage connecting the stay to the top thimble is a “soft shackle” an increasingly widely used device for attaching anything to something else, as one would with a stainless shackle

There are a pair of running backstays connected to the spar.

The running backstays are attached to the mast just below the upper spreaders and opposite the point where the inside stay connects to the spar. This is high enough that with the third ref in, the head of the sail is below the runners. The end of the boom is far enough forward that both runners can be set up and the boat can be gybed and tacked without handling the runners. An extra insurance policy on hard conditions.

These are tensioned by a 2:1 tackle led through Antal thimbles, to a clutch, thimble and again with enough tail to get to any winch.

I used himbles again on the flying part of the runners: They are light (does not hurt so much when it hits you in the head….)strong & inexpensive-A trifecta that is hard to beat.

The running backstays are led through a thimble secured on the transom and forward through a clutch to another thimble permitting any winch to be used to tension them

The serendipitous aspect of the runners and where they land in the spar is that with the third reef in the mainsail the head of the sail is below where the runners attach to the mast AND the runners are sufficiently aft of the end of the boom, so BOTH runners can be set up when it is really howling and the boat can be tacked or gybed without attending to the runners. In this configuration the assumption is the inside stay will be deployed so the spar has another level of security to defend against damage.

The runner tails are dead ended on the same chain plate as the standing backstay, led up through the flying part of the runners, back to a thimble and forward through a clutch, thimble and so to any winch available.